The pace of growth of economy coupled with infrastructural development is generating huge business for Engineering Congloromates to the extent they offload their manufacturing activities to reliable and committed vendors like us.

Usage of advance software like Radan helps fast preparation of these developed views of the product for flat processing. The developed drawings are sent to programming department which prepares program for Laser or Plasma cutting depending on the thickness.

CNC turret punching is a cost effective method for cutting sheet steel in moderate to long runs. It has vast tooling potential for the increased versatility.

We have State of the art machinery, High capacity material handling cranes, Latest software tools and Skilled work force to produce best results in each of these there areas.

Traditionally CNC programming is done on the shop floor, on the CNC controller of press brake. However, it can result in wrong bending resulting in scrap if the drawings are interpreted wrongly resulting in wastage of material.

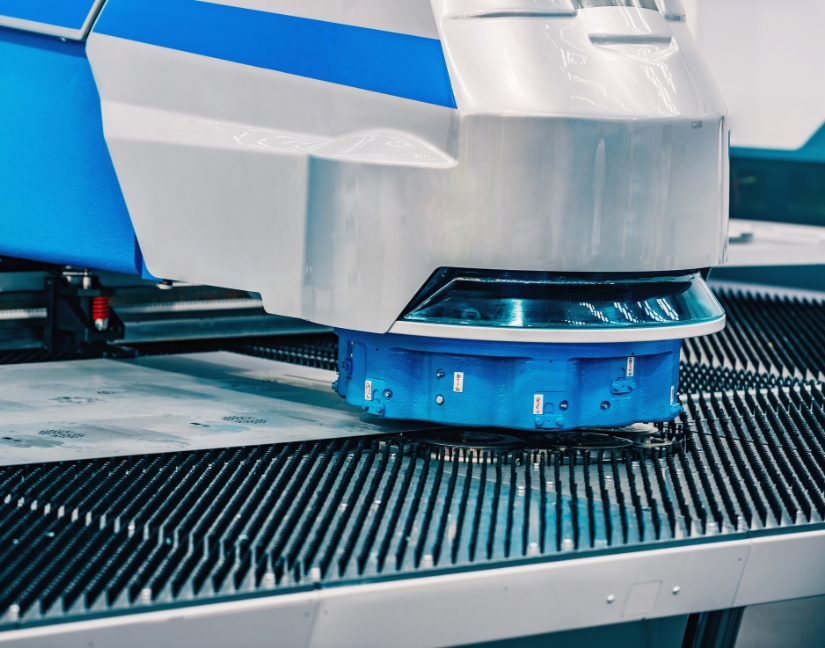

The CNC laser cutting machine is used to cut metals such as Mild Steel, Stainless Steel and Aluminum with high precision and speed.

Welding is one of the most critical operations in fabrication of sheet steel fabrication of assemblies. To some extent the strength of the assemblies depend on the quality of welding. Hence, we take utmost care in welding operation.

In Oxyfuel cutting fuel gases and oxygen are used to cut sheet steel. Oxyfuel cutting is a chemical reaction between pure oxygen and steel to form iron oxide.

The fabricated assemblies are sent for surface preparation and coating. A sheet steel assembly surface needs to be prepared for coating as there are several not uniformities and impurities that can act as a hindrance for protective coating.